Valve Casting Process

Mold Preparation

Based on the valve’s design drawings and dimensions, molds are made to fit the shape of the valve. Sand molds or metal molds are typically used.

Metal Melting

The appropriate metal alloy is melted according to the valve’s material requirements, ensuring that the alloy composition meets the standards.

Metal Pouring

The molten metal alloy is slowly poured into the prepared mold, ensuring that it fills the mold completely and preventing the formation of bubbles.

Cooling and Solidification

After the metal has fully cooled and solidified, the valve is removed from the mold.

Deburring

The valve’s surface is cleaned of burrs and uneven parts to ensure the valve’s appearance and surface quality.

Machining and Assembly

The valve undergoes further machining and assembly, as needed, to achieve the required precision and functionality.

Inspection and Testing

Rigorous inspection and testing are conducted on the completed valve to ensure its sealing, pressure resistance, and functional reliability.

Surface Treatment

Depending on requirements, the valve may undergo surface treatment, such as coating with anticorrosive layers or plating.

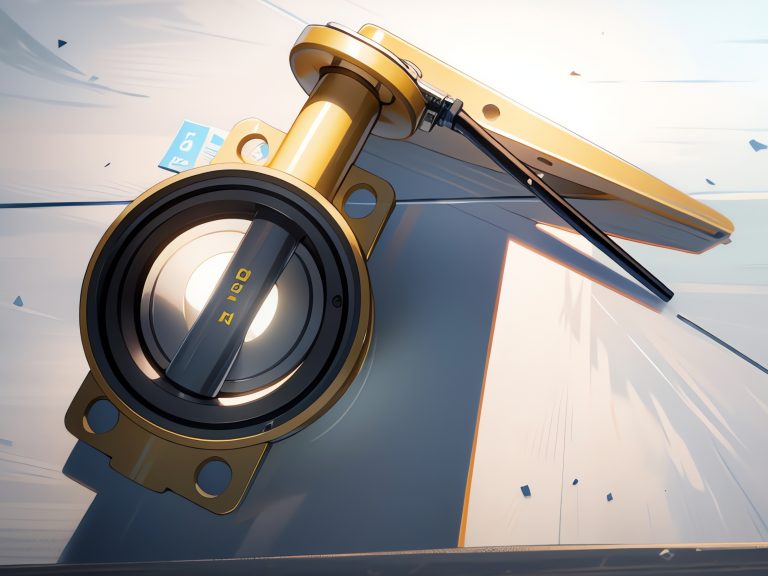

Featured Products

Feugiat pretium nibh ipsum consequat commodo.

About Us

If you have any questions, please call:+86 13075786671

Latest News

Feugiat pretium nibh ipsum consequat commodo.

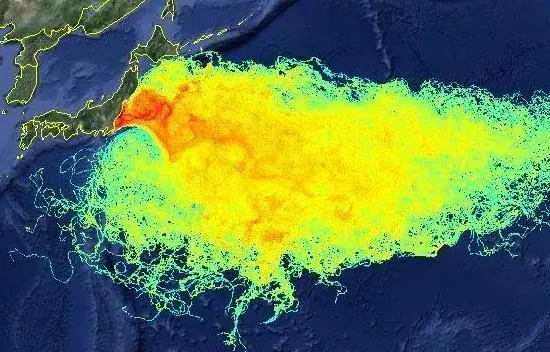

Hot Point-Discharge of Nuclear Polluted Water in Japan

When it comes to the nuclear industry and the handling…

‘’The Switch of the Universe‘’

《Flying Valve》 With the rapid development of technology, China’s valve…

The selection methods for common valves

1 Valve selection key points 1.1 Clearly define the purpose…

The reasons for the cracking of large-diameter flanges

A company’s dehydrogenation reactor experienced a leak at the takeover…

What are the main methods of pipeline inspection

Pipeline internal inspection technologies include television inspection (CCTV inspection), periscope…