When it comes to the nuclear industry and the handling of radioactive materials, we must pay close attention to the recent issue of Japan’s plan to discharge nuclear-contaminated water. In this discussion, the highlighted points revolve around the valves and materials used in the nuclear industry, as well as the risks and concerns associated with nuclear pollution.

The complexity of the nuclear industry necessitates the use of high-quality valves and specialized materials to ensure the safety and reliability of operations. From design and manufacturing to material selection, everything must adhere to strict standards.

Within the nuclear industry, the processing of radioactive materials involves various equipment and control measures, including some potential types of valves:

Isolation Valves:

These are used to isolate different sections to stop the flow of fluids or gases when necessary. In the nuclear industry, these might be used to isolate radioactive materials, ensuring that the flow can be cut off when needed.

Control Valves:

These are employed to regulate the flow of fluids or gases, often with adjustable openings as required. They could be used in handling and distributing radioactive substances.

Safety Valves:

These are used to release pressure when the system becomes overpressurized, preventing system rupture. In nuclear facilities, these valves can prevent pressure buildup, ensuring the safety of system operation.

Radioactive Material Control Valves:

Specially designed for handling radioactive materials, these valves may possess special seals and materials to prevent radioactive substance leaks.

Contamination Barrier Valves:

Used during the processing of radioactive materials, these valves ensure the prevention of contamination spread. These valves might require high sealing capabilities.

Given the extremely high safety and protection requirements involved in handling radioactive materials, the valve materials used must possess special properties to ensure effective operation in radioactive environments and prevent leaks.

Here are some potential valve materials that could be used in the nuclear industry:

Stainless Steel:

Stainless steel is often used in the manufacturing of valves for the nuclear industry due to its excellent corrosion resistance and high-temperature durability. 316 stainless steel is a common choice due to its heightened resistance to radioactive substances.

Alloy Materials:

Some high-temperature alloy materials such as niobium, tantalum, and zirconium alloys are also frequently used in manufacturing valves for the nuclear industry due to their high-temperature and corrosion resistance.

Ceramic Materials:

In specific applications, ceramic materials can be used in valve manufacturing because they perform well in high-temperature and corrosive environments. Polytetrafluoroethylene (PTFE):

This high-performance plastic material boasts excellent chemical corrosion resistance and can be used for valve seals in certain special cases within the nuclear industry.

Lead Lining:

Some nuclear facilities may require lead lining to absorb radioactive radiation and prevent leaks. In certain cases, the exterior of valves can be enveloped with lead lining.

Safety First: High-Quality Practices in the Nuclear Industry

The employment of these high-quality manufacturing practices and material selections reflects the nuclear industry’s commitment to safety. This also underscores the critical role that technological progress and innovation play in ensuring the sustainability of the nuclear industry, with safety being an uncompromising core principle.

Beyond Progress: Unveiling Concerns about Nuclear Pollution

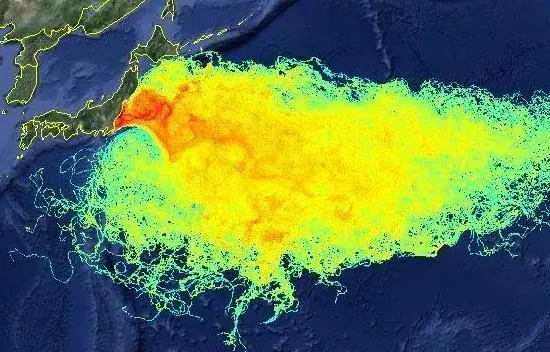

However, this discussion has spurred concerns about nuclear pollution. The risks associated with nuclear pollution are not confined solely to the nuclear industry itself; they can have far-reaching impacts on the environment and human health. The leakage of radioactive substances can lead to soil, water, and atmospheric contamination, disrupting ecological balance. Moreover, prolonged human exposure to radioactive materials can trigger cancer, genetic mutations, and other health issues.

Global Collaboration: Addressing Nuclear Pollution’s Cross-Boundary Impact

This cross-boundary impact reminds us of the paramount importance of global collaboration. Countries should strengthen information sharing, technological cooperation, and the establishment of laws and regulations to address environmental challenges like nuclear pollution, ensuring the safeguarding of the collective human future.

Balancing Act: Prioritizing Environmental Protection in Nuclear Development

This case serves as a reminder that as the nuclear industry pursues energy generation, environmental protection and human health must be prioritized. Technological advancements and innovation should be employed to ensure the safe operation of the nuclear industry and minimize its adverse environmental impact. In taking action, governments, industries, and the international community must jointly endeavor to achieve a balance between sustainable development and environmental preservation within the nuclear industry.

Sustainable Goals: Aligning the Nuclear Industry with Global Objectives

The development of the nuclear industry must be closely aligned with sustainable development goals. Beyond investments in valves and materials, we also need to bolster research efforts, promote cleaner and safer nuclear technologies, and enhance our capacity for nuclear waste management and disposal.

Therefore, the concerns raised by Japan’s plan to discharge nuclear-contaminated water are not limited to a national-level issue; they represent a global challenge that necessitates collective contemplation and resolution. Whether in the utilization of advanced valves and specialized materials within the nuclear industry or in addressing the risks posed by nuclear pollution, we should draw lessons from these discussions to seek a more balanced path for the future development of the nuclear industry.

A Call for Action: Collective Responsibility in Shaping the Future of Nuclear Energy

As individuals, we should also focus on the sustainability of energy consumption and support alternative solutions such as renewable energy, collectively contributing to reducing our reliance on nuclear energy and driving the transition to green energy.